SMART 100.1 Shift

Box -

Product Support Page

Last updated 5/4/17

Forced Four SMART 100.1

INSTALLATION INSTRUCTIONS

-

If used with a TCU or other method of controlling the

transmission, only one way of controlling the transmission

should be powered on at one time to prevent unexpected

control of the transmission or damage to the TCU. Use of our

TCU package or similar suitable switch/relay must be used to

power the TCU or shift box one at a time.

-

Use of diodes, provided with the TCU package, is necessary

to prevent damage to TCU.

-

The SMART 100.1 must be properly configured for your

transmission type before operating

-

Mount the SMART 100.1 unit in the vehicle cabin away from

heat and moisture, routing wires away from a CDI ignition

box or high voltage coil wiring recommended to prevent

erratic behavior.

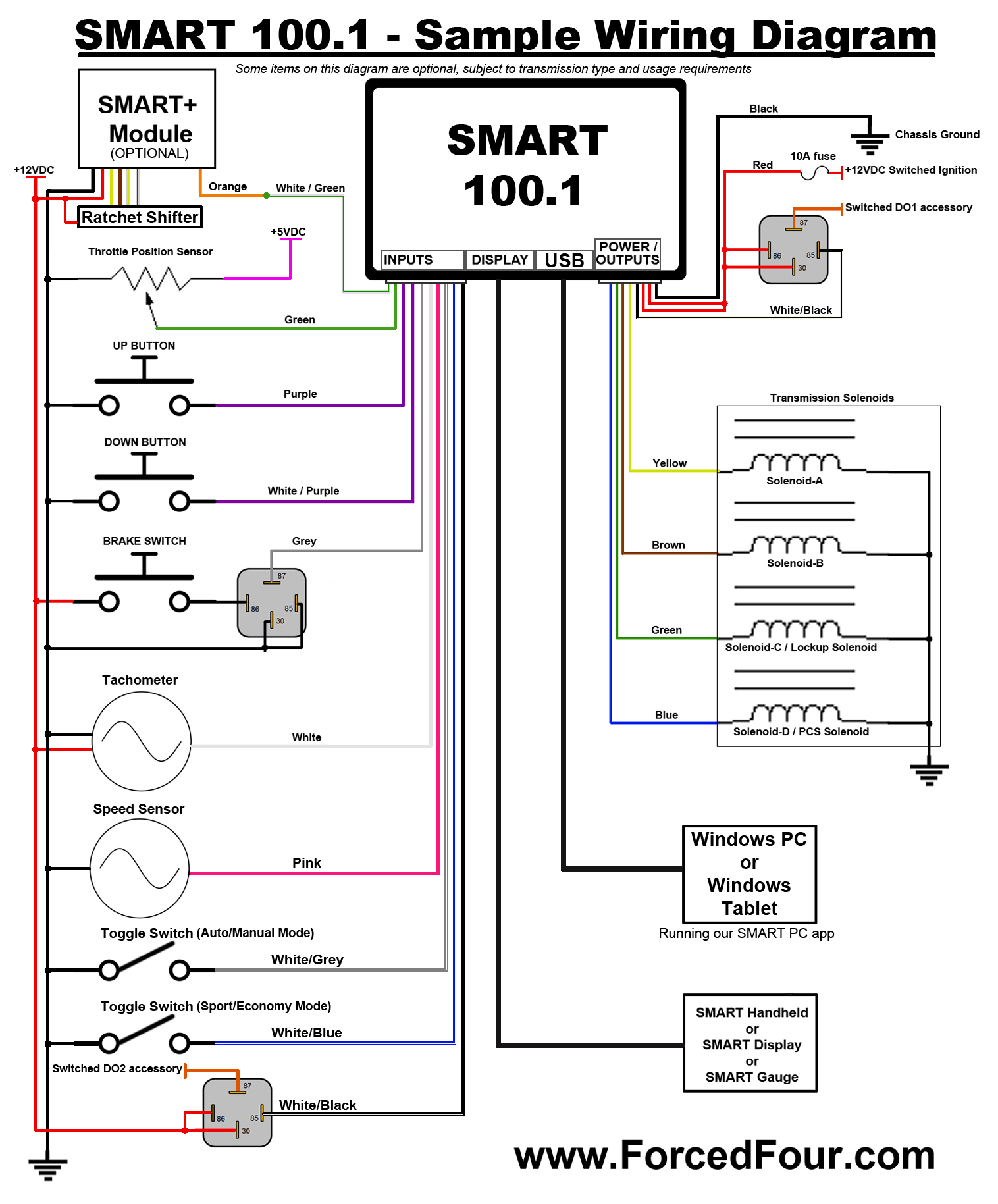

Wiring the SMART 100.1 shift box:

Any wires not used should be capped to prevent damage or

unwanted behavior!

USB

type mini connector

Display 8 pin

connector

Main 8 pin

connector [power, and outputs]

-

Yellow wire goes to Shift Solenoid A (SOL-A) (3A max)

-

White/Black wire is Digital Output #1 (DO1) switched to

ground when active (500mA max)

-

Brown wire goes to Shift Solenoid B (SOL-B) (3A max)

-

Black wire is ground, connect to a good clean chassis ground

-

Green wire goes to Shift Solenoid C OR Lockup Converter

(SOL-C) (3A max)

-

Red wire is +12 volt power from the ignition switch or TCU

fuse switched (18VDC max)

-

Blue wire goes to Shift Solenoid D OR Pressure Control

Solenoid (SOL-D) (8A max)

-

Red wire is +12 volt power from the ignition switch or TCU

fuse switched (18VDC max)

Main 10 pin

connector [Inputs]

-

Green wire is Analog Input #1 (AI1) typically TPS (0-5VDC)

-

White/Green wire is Analog Input #2 (AI2) (0-5VDC) OR

Digital Input #6 (DI6) (Active when pulled low to ground) Do

not exceed 5V on this input!

-

Purple wire is Digital Input #1 (DI1) up-shift button

(Active when pulled low to ground)

-

White/Purple wire is Digital Input #2 (DI2) down-shift

button (Active when pulled low to ground)

-

Grey wire is Digital Input #3 (DI3) brake switch (Active

when pulled low to ground)

-

White/Grey wire is Digital Input #4 (DI4) (Active when

pulled low to ground)

-

White/Blue wire is Digital Input #5 (DI5) (Active when

pulled low to ground)

-

White/Black wire is Digital Output #2 (DO2) switched to

ground when active (500mA max)

-

Pink wire is speed signal input for vehicle speed MPH

-

White wire is engine speed input for engine RPM

Confused? Contact us at

sales@forcedfour.com

Forced Four SMART 100.1

GENERAL USAGE INSTRUCTIONS

-

Once installed, this shift box is simple to use. Simply

press the up-shift button to advance to the next gear, or

press the down-shift button to drop to a lower gear.

-

This shift box will boot up in 2nd gear, unless configured

differently by the user, every time as a safety in case the

shift box would ever reboot due to a power connection

problem.

-

By default the downshift protection RPM is 4500RPM.

-

TCU mode will be active by default if not in limp mode or

disabled by user, when a manual shift is made you must

disable and re-enable TCU mode to make active again.

-

TPS and speed signal inputs required for TCU mode to be

active.

-

Brake switch recommended for most

applications, by default the digital input for brake switch

is active when pulled low to ground, this can be

accomplished with a relay. Alternatively you can invert the

input on the inputs tab and connect the digital input

directly to the 12V brake switch signal. If using LED bulbs

on your car it may be necessary to use a 1K resistor on the

digital input connected to ground to ensure the input is

pulled low when the brake switch isn't active. With

incandescent bulbs this is not required as the bulb filament

will pull the signal low.

-

TPS must be calibrated to prevent out of range error codes

which may cause limp mode.

-

Speed signal pulse per mile (PPM) must be properly set for

accurate speed measurement.

-

Engine speed pulse per revolution (PPR) must be properly set

for accurate engine speed measurement.

-

Digital inputs may be configured for your purpose, inputs

are active when pulled low to ground. You can invert the

signal on the inputs tab making the input active when pulled

high. High is considered over 2.5VDC and the inputs are 12V

tolerable so direct connection to inputs like the factory

overdrive off switch works just fine. When the signal is

inverted a pull down resistor of 1K is recommended connected

between the digital input and ground. This will guarantee

the signal is low when power is removed. The inputs are

pulled high to 5V internally through a 10K resistor.

-

Digital outputs may be configured for your purpose, when

active the output will be connected to ground, maximum 500mA

current draw, use of a relay is necessary to switch higher

current loads.

-

To use the RPM up-shift feature, you must set the shift

points to your desired RPM in the menu. Set the shift point

~1000RPM sooner than you want the shift to be made to start,

and adjust as necessary. This is due to the delay inside the

transmission to engage the clutches. You must enable the

UP-SHIFTER in the menu to use this feature.

-

The overdrive off feature can be used by up-shifting to

overdrive gear. Press and hold the up button until the O/D

off LED illuminates and the shift box downshifts to the next

lower gear. To turn O/D back on, up-shift to the max gear

and press and hold the up button until the O/D off LED turns

off and the shift box up-shifts to overdrive gear. Overdrive

off can be configured to a digital input and connected to

the factory overdrive off switch. Using this switch requires

a 1K resistor connected between digital input and ground to

properly pull the signal low when switch is open.

-

Click on the question mark for helpful hints on each

application tab page.

-

Note that the shifts are made at full line pressure,

learning the timing on when to make the shift will make

using this shift box much more pleasurable on the street.

-

Download and install the PC app from our website,

www.forcedfour.com/downloads.htm

driver installation may be necessary. Connect the USB cable

to your PC and turn on the shift box before launching the PC

app. Select the com port and press connect.

-

As you make your changes on the PC app the SMART 100.1 is

updated instantly when you press the enter key. Changes are

not saved permanently to the flash memory though until you

press the save changes button on the connect tab. If you

fail to save changes, the settings will be reverted back

after a power cycle.

-

Data log files will be saved to c:\ForcedFour\ directory on

your PC. Use the Haltech Datalog Viewer or Megasquirt

Datalog Viewer to view saved SMART datalogs. Download

Haltech Datalog Viewer

here.

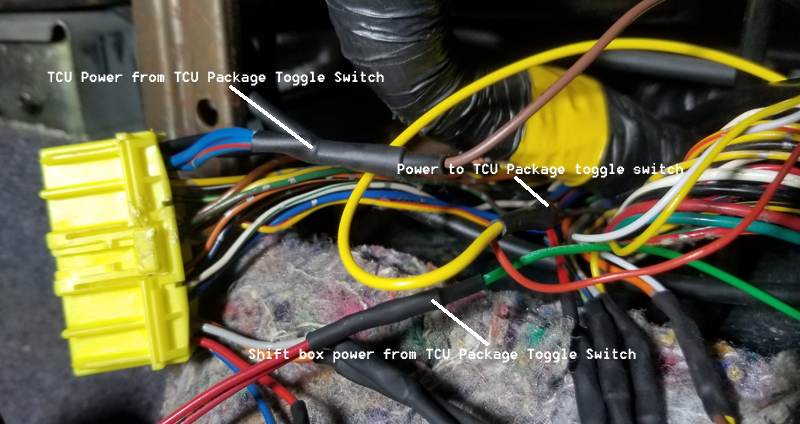

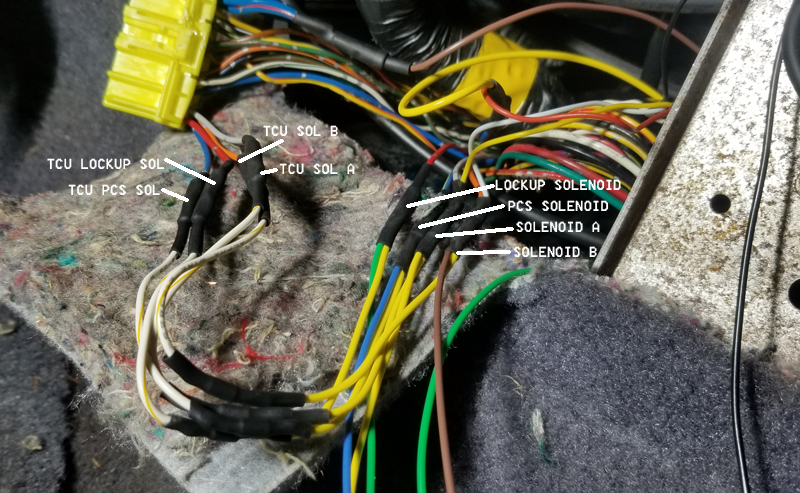

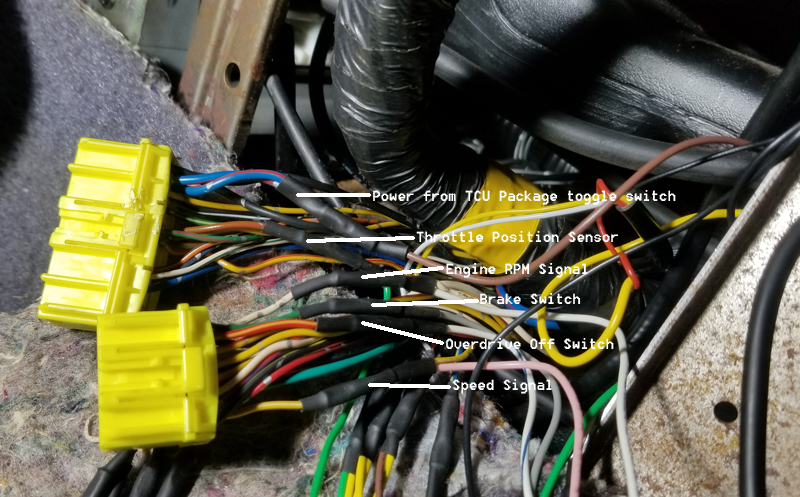

Install pictures on a 2G DSM with factory auto retaining TCU

Updating the firmware:

- The most recent SMART 100.1 firmware version is 007

- Please send an e-mail to

sales@forcedfour.com to inquire about updating your

firmware.

Downloading the PC software:

Confused? Contact us at

sales@forcedfour.com

|