SMART 100 Shift

Box -

Product Support Page

Last updated 7/25/16

SMART 100 INSTALLATION INSTRUCTIONS

-

If used with a TCU or other method of controlling the

transmission, only one way of controlling the transmission

should be powered on at one time to prevent unexpected

control of the transmission or damage to the TCU. Use of our

TCU package or similar suitable switch/relay must be used to

power the TCU or shift box one at a time.

-

Use of diodes, provided with the TCU package, is necessary

to prevent damage to TCU.

-

The SMART 100 must be properly configured for your

transmission type before operating

-

Use of either the SMART handheld, SMART display, or SMART

gauge is required to configure device via the on screen

menu.

-

Mount the SMART 100 unit in the vehicle cabin away from heat

and moisture, routing wires away from a CDI ignition box or

high voltage coil wiring recommended to prevent erratic

behavior.

General Usage Instructions:

-

Once installed, this shift box is simple to use. Simply

press the up-shift button to advance to the next gear, or

press the down-shift button to drop to a lower gear.

-

This shift box will boot up in 3rd gear, unless configured

differently by the user, every time as a safety in case the

shift box would ever reboot due to a power connection

problem.

-

By default the downshift protection RPM is 4500RPM, see the

menu below to change this, or disable the downshift

protection.

-

To use the RPM up-shift feature, you must set the shift

points to your desired RPM in the menu. Set the shift point

~1000RPM sooner than you want the shift to be made to start,

and adjust as necessary. This is due to the delay inside the

transmission to engage the clutches. You must enable the

UP-SHIFTER in the menu to use this feature.

-

The overdrive off feature can be used by up-shifting to

overdrive gear. Press and hold the up button until the O/D

off LED illuminates and the shift box downshifts to the next

lower gear. To turn O/D back on, up-shift to the max gear

and press and hold the up button until the O/D off LED turns

off and the shift box up-shifts to overdrive gear.

-

The torque converter lock-up feature, when enabled, will

illuminate the green LED when the solenoid is turned on

-

Note that the shifts are made at full line pressure, if soft

shift is not configured or using pressure control solenoid

is not possible, learning the timing on when to make the

shift will make using this shift box much more pleasurable

on the street.

Forced Four SMART 100

INTERFACE MENU

To enter the menu:

Downshift to 1st gear then press and hold down shift

button until menu opens

Basic tips for easier menu navigation:

Default values are shown as underlined

Bold text is word for word what the shift box

will display

You can skip to the next menu option without

waiting for the text to be displayed

Brake switch will toggle some values the opposite

direction

Up button selects or toggles an item/value, down

button advances to the next menu item

Sub menus will return back to the heading of the sub

menu just exited

Main menu items have a double beep; sub menu items have

a single beep

Menu will automatically save settings and exit

after ~ 6 seconds of user inactivity

MENU

INTERFACE

(Up to select, down for next)

BRIGHTNESS = 5

(Set display brightness 1-5)

SCROLL SPEED = 3 (Set text scroll speed

1-5)

AUDIO = ENABLED/DISABLED

(This option mutes normal beeps, doesn't affect menu beeps)

DOWN SHIFT PROTECTION

(Up to select, down for next)

DOWN SHIFT PROTECTION = ENABLED/DISABLED

(Enable or disable down-shift protection feature)

DOWN SHIFT PROTECTION = 4500

(Configurable from 3500RPM - 7000RPM)

UP SHIFTER CONFIG (Up to select, down for next)

UP SHIFTER = ENABLED/DISABLED

(Enable or disable up-shifter feature)

1-2 SHIFT POINT = 5500 (Set the 1-2 shift

point, configurable from 5000-12000RPM, 0=disabled)

2-3 SHIFT POINT = 5500 (Set the 2-3 shift

point, configurable from 5000-12000RPM, 0=disabled)

3-4 SHIFT POINT = 5500 (Set the 3-4 shift

point, configurable from 5000-12000RPM, 0=disabled) *

4-5 SHIFT POINT = 5500 (Set the 4-5 shift

point, configurable from 5000-12000RPM, 0=disabled) *

5-6 SHIFT POINT = 5500 (Set the 5-6 shift

point, configurable from 5000-12000RPM, 0=disabled) *

OD DOWN SHIFT CONFIG (Up to select, down for next)

OD DOWN SHIFTER = ENABLED/DISABLED

(Enable or disable down-shifter feature)

MAX TPS = 50% (Set the maximum throttle

position allowed on overdrive before auto downshifting, 10-90)

DEBOUNCE = 50 (Maximum duration above MAX

TPS value before auto downshifting, 25-75)

LOCKUP CONFIG

(Up to select, down for next)

LOCKUP = ENABLED/DISABLED

(Enable or disable lockup feature)

LOCKUP SOLENOID = SOL-C (Configure which

solenoid output is lockup clutch) (MUST BE SOLENOID C)

1ST LOCKUP RPM = 0 (Lockup

above set RPM in 1st gear, 0=disabled, 1500-5500)

2ND LOCKUP RPM = 3000 (Lockup above set

RPM in 2nd gear, 0=disabled, 1500-5000)

3RD LOCKUP RPM = 3000 (Lockup above set

RPM in 3rd gear, 0=disabled, 1500-5500)

4TH LOCKUP RPM = 3000 (Lockup above set

RPM in 4th gear, 0=disabled, 1500-5500) *

5TH LOCKUP RPM = 3000 (Lockup above set

RPM in 5th gear, 0=disabled, 1500-5500) *

6TH LOCKUP RPM = 3000 (Lockup above set

RPM in 6th gear, 0=disabled, 1500-5500) *

MAX TPS = 70 (Turn off lockup above set

TPS 10-100%)

MIN TPS = 0

(Turn off lockup below set TPS 0-90%)

BRAKE SW = YES/NO (Turn off lockup when

brake pedal is pressed)

DEBOUNCE = 750 (Lockup debounce for

smoothing 250-1500)

PCS CONFIG

(Up to select, down for next)

PCS = ENABLED/DISABLED

(Enable or disable soft shift / line pressure control feature

for downshifts)

PCS SOLENOID = D (Configure which solenoid

output is PCS) (MUST BE SOLENOID D)

PCS FREQUENCY = 33Hz (Configure the PCS

solenoid operating frequency, 30-150Hz)

SOFT SHIFT = 15 (Downshift firmness from

10=firm and 20=soft)

ANALOG INPUTS

(Up to select, down for next)

AI1 = RATCHET / TPS / NONE

(Configure Analog Input #1)

AI2 = RATCHET / TPS / NONE

(Configure Analog Input #2)

DIGITAL INPUTS

(Up to select, down for next)

DI1 = UP-BTN / DN-BTN / BRAKE-SW / STALL-UP / O/D-OFF /

NONE

(Configure Digital Input #1)

DI2 = UP-BTN / DN-BTN / BRAKE-SW / STALL-UP / O/D-OFF /

NONE

(Configure Digital Input #2)

DI3 = UP-BTN / DN-BTN / BRAKE-SW / STALL-UP / O/D-OFF /

NONE

(Configure Digital Input #3)

DIGITAL OUTPUTS

(Up to select, down for next)

DO1 = O/D-OFF / TQU-RED / WINDOWED / STALL-UP / NONE

(Configure Digital Output #1)

STALL UP MODE

(Up to select, down for next)

STALL UP = ENABLED/DISABLED

(Enable or disable stall up control feature)

STALL UP TPS = 90% (Enter stall up mode when TPS

above this value with brake switch active)

STALL UP INPUT = YES/NO

(Use external input to activate stall up mode)

MAX STALL RPM = 5000 (Disable stall up

mode above this RPM)

WINDOWED MODE

(Up to select, down for next) (All below settings must be true

for output to be enabled)

WINDOWED MODE = ENABLED/DISABLED

(Enable or disable windowed output feature)

MIN TPS = 10% (Output enabled when TPS above

minimum)

MAX TPS = 90% (Output enabled when TPS below

maximum)

BRAKE SW = ON / OFF / ANY (Output enabled

if brake switch pressed, not pressed, or either position)

MIN RPM = 1000 (Output enabled when RPM

above minimum, 1000-12000)

MAX RPM = 9000 (Output enabled when RPM

below maximum, 1000-12000)

GEAR 1 = YES / NO (Output enabled in gear

1)

GEAR 2 = YES / NO (Output enabled in gear

2)

GEAR 3 = YES / NO (Output enabled in gear

3)

GEAR 4 = YES / NO (Output enabled in gear

4) *

GEAR 5 = YES / NO (Output enabled in gear

5) *

GEAR 6 = YES / NO (Output enabled in gear

6) *

ADVANCED

(Up to select, down for next)

SMART VERSION

(Up button to display current software version of SMART gear

display or SMART handheld)

PULSE PER REV = 2

(Number of pulse per engine revolution - 4 cylinder=2, 6

cylinder=3, 8 cylinder=4)

DISPLAY RPM

(Up button to display current engine RPM, useful for verifying

proper installation)

CALIBRATE TPS

(Up button to calibrate) (Hold full throttle until beep then

release throttle until beep)

FULL THROTTLE

(Press and hold full throttle until beeps)

ZERO THROTTLE

(Release throttle completely until beeps)

CALIBRATED (Confirmation of calibration)

DISPLAY TPS VALUE

(Up button to display current throttle position, useful for

verifying proper installation)

DISPLAY AI1 VALUE

(Up button to display raw AI1 value 0-255, useful for verifying

proper installation)

DISPLAY AI2 VALUE

(Up button to display raw AI2 value 0-255, useful for verifying

proper installation)

DISPLAY BRAKE SW

(Up button to display current brake switch value, useful for

verifying proper installation)

FORWARD GEARS = 3/4/5/6

(how many forward gears the transmission has)

ENTRY GEAR = 3

(Default gear for bootup, recommend 3rd in case of a power

supply glitch and reboot during normal use)

UP

SHIFTER DEBOUNCE = 120

(Debounce auto shift to prevent double shift, configurable from

50-250ms)

SHIFT SOL CONFIG (Up to select, down for next)

(Default varies depending on transmission type specified when

ordered)

1ST-GEAR

(Configure first gear

solenoids)

A = ON/OFF

B = ON/OFF

C = ON/OFF

D = ON/OFF

2ND-GEAR

(Configure second gear solenoids)

A = ON/OFF

B = ON/OFF

C = ON/OFF

D = ON/OFF

3RD-GEAR

(Configure third gear solenoids)

A = ON/OFF

B = ON/OFF

C = ON/OFF

D = ON/OFF

4TH-GEAR

(Configure fourth gear solenoids) *

A = ON/OFF

*

B = ON/OFF

*

C = ON/OFF

*

D = ON/OFF

*

5TH-GEAR

(Configure fifth gear solenoids) *

A = ON/OFF

*

B = ON/OFF

*

C = ON/OFF

*

D = ON/OFF

*

6TH-GEAR

(Configure sixth gear solenoids) *

A = ON/OFF

*

B = ON/OFF

*

C = ON/OFF

*

D = ON/OFF

*

RESTORE DEFAULTS

(Up to select, down for next)

CONFIRM? (Up button to confirm the restore

defaults)

ABOUT (Up button displays current software version and

product details)

SAVE AND EXIT? (Up button to save and exit, down will

advance back to the first menu item)

EXIT WITHOUT SAVING

(Up button to exit without saving changes)

*

Items marked with a * may not be shown depending on the number

of forward gears configured

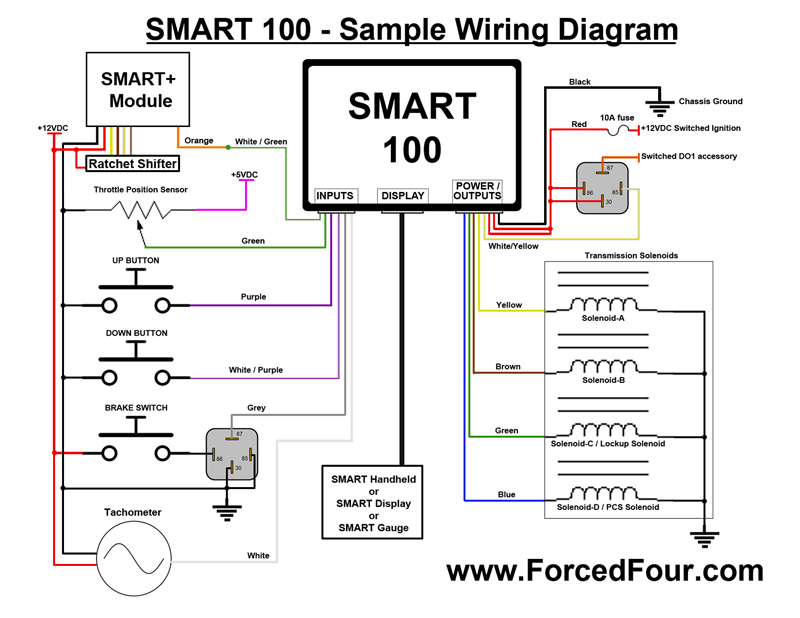

Wiring

instructions:

Wiring the SMART 100 shift box:

Any wires not used should be capped to prevent damage or

unwanted behavior!

Display 8 pin

connector

8 pin [power and

output] plug

-

Red wires are +12 volt power from the ignition switch,

connect both wires together

-

Black wire is ground, connect to a good clean chassis ground

-

Yellow wire goes to Shift Solenoid A

-

Brown wire goes to Shift Solenoid B

-

Green wire goes to Shift Solenoid C OR Lockup Converter

-

Blue wire goes to Shift Solenoid D OR Pressure Control

Solenoid

-

White/Black wire is Digital Output #1 (DO1) configured as

spare by default

6 pin [input]

plug

-

Green wire is Analog Input #1 (AI1) configured as TPS sensor

by default

-

White/Green wire is Analog Input #2 (AI2) configured as

spare input by default

-

Purple wire is Digital Input #1 (DI1) configured as up shift

button by default, pull low to ground

-

White/Purple wire is Digital Input #2 (DI2) configured as

down shift button by default, pull low to ground

-

Grey wire is Digital Input #3 (DI3) configured as brake

switch by default, pull low to ground

-

White wire is Digital Pulse Input #1 (DPI1) configured as

the RPM input / tach signal input

Updating the firmware:

- The most recent SMART 100

firmware version is 001

- Please send an e-mail to

sales@forcedfour.com to inquire about updating your

firmware. Please note this shift box does not support

USB firmware updates and will need to be shipped to

Forced Four to be updated.

- (Note:

All settings will be set to factory defaults when

the firmware is updated)

Confused? Contact us at

sales@forcedfour.com

|